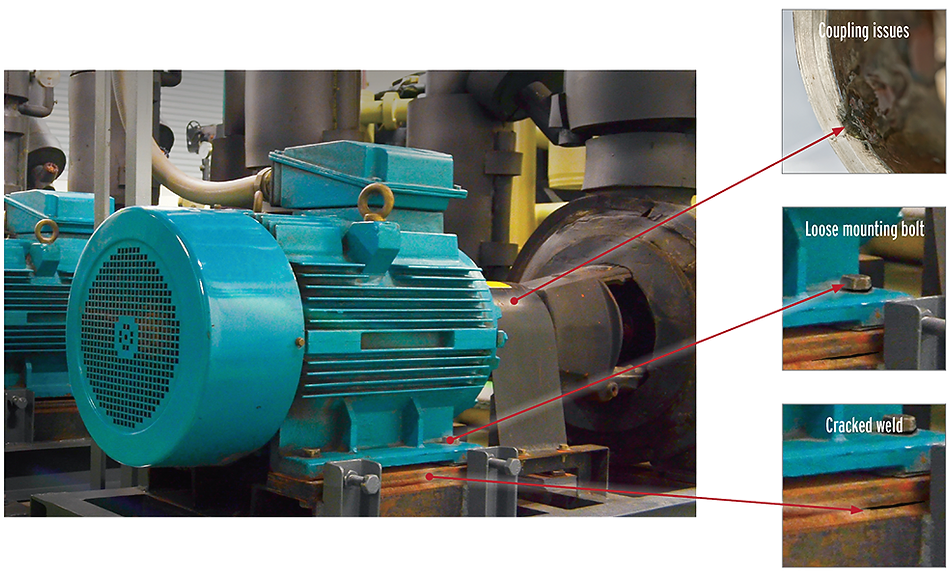

Rocky Mount Electric Motor utilizes motion amplification with vibration analysis to discover issues that are impossible to see during normal motor operation. This technology works to keep your factory floor from grinding to a halt. Our service uses state-of-the-art predictive technology, the Iris M Camera, which enables us to see problems before they become production problems.

Motion amplification and vibration analysis find problems with ease.

Motion amplification works alongside vibration analysis to extend the life of your motor. It measures deflection, displacement, movement, and vibration that can’t be detected by conventional methods. By combining video camera technology with an enhanced processing algorithm, this service sees your equipment differently to reveal persistent, hidden issues. This dramatically reduces or outright eliminates downtime. By working with Rocky Mount Electric Motor, you find better solutions for your electric motor systems to keep operations running. Through motion amplification and vibration analysis, we help you find the root cause of problems to solve them before them ever become a larger issue.

Save more. Work more. Earn more.

When you have a service plan with Rocky Mount Electric Motor, the benefits of predictive maintenance quickly become clear. We keep your factory floor humming by helping you plan maintenance, repairs, and replacements to improve your uptime and save you money.

To see motion amplification in action, and to learn more about our predictive maintenance plans, reach out today!