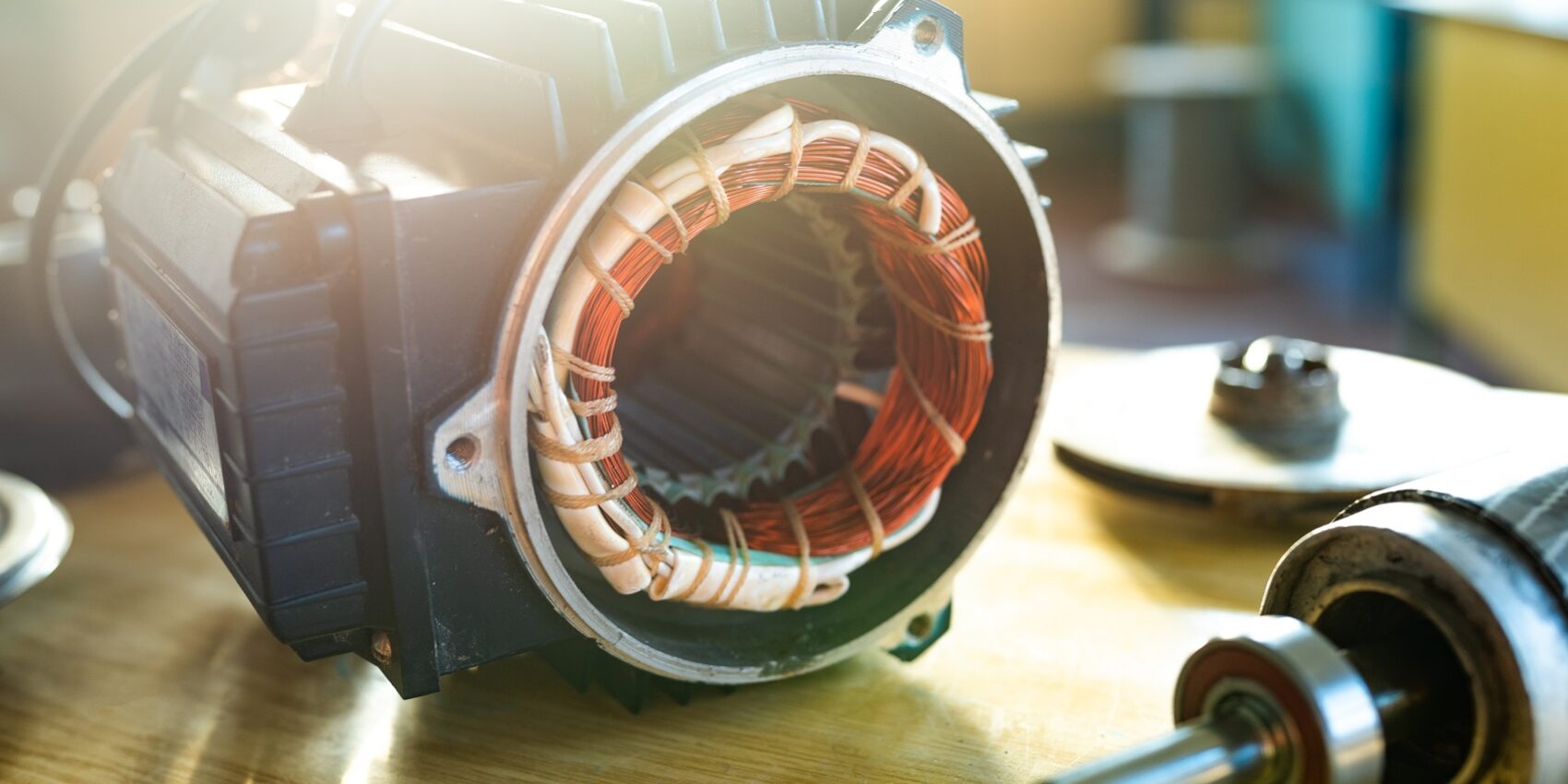

Electric motors are the backbone of countless industries–powering pumps, conveyors, fans, compressors, and more. When a motor fails, operations can grind to a halt, leading to costly downtime and potential revenue loss. While replacing a failed motor might seem like the simplest solution, rewinding your electric motor is often the smarter, more sustainable, and cost-effective choice.

Previously, we’ve shared our process for rewinding electric motors, however today we will take a closer look at the benefits of rewinding electric motors, and why Rocky Mount Electric Motor should be your first call when your motor needs attention.

Benefits of Rewinding Electric Motors

- Extending the Life of Your Investment: Electric motors are not cheap. Whether you’re running a small shop or a large industrial facility, your motors are your money. Rewinding allows you to breathe new life into an existing motor by replacing the damaged windings and restoring it to like-new performance. Instead of spending on a replacement, you’re extending the service life of equipment you already own.

- Reduce Downtime and Maintain Continuity: Motor failure can mean unexpected downtime, which is something no business can afford. Rewinding can often be completed faster than ordering and installing a new motor, especially if it’s a specialty model that may be more difficult to source. With expert service from Rocky Mount Electric Motor, you get your equipment back in operation quickly and reliably.

- Preserve Discontinued Equipment: In some cases, the original motor may be discontinued or have long lead times for replacement–and nobody wants to spend months waiting on an engine. Rewinding keeps legacy systems running and helps avoid the costly re-engineering or reconfiguring that may be required with a new motor.

- Support Sustainability: God gave us one Earth, and it’s our job to keep it clean. Rewinding is an environmentally responsible choice. Manufacturing new motors consumes raw materials and energy, whereas rewinding reuses the existing frame and components. By rewinding, you’re reducing waste and supporting sustainability without sacrificing performance.

Trusting Rocky Mount

If you’re facing electric motor failure, don’t assume replacement is your only option. Electric motor rewinding with Rocky Mount Electric Motor is the smarter, cleaner, and more cost-effective solution. We’ll restore your motor to peak performance and help you avoid unnecessary downtime and expense. With our experience, advanced capabilities, and commitment to quality, there’s no better partner to trust with your critical equipment. Rocky Mount Electric Motor is an EASA Accredited repair shop, so you know your motor will be repaired following stringent industry guidelines. If you’re curious to know more about our standards, give us a call today!

Predictive Maintenance

Running to failure is the most costly way to manage your assets. By setting up predictive maintenance with Rocky Mount Electric Motor, you can detect problems earlier with your electrical equipment, allowing you to better control when costly repairs and minimize risk of unexpected downtime. Rocky Mount Electric Motors’ mission is to honor God by serving its customers, employees and the community, so reach out to us today to see what we can do for you.