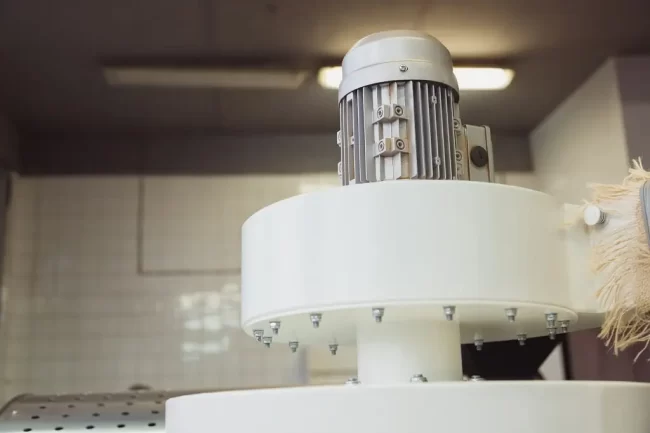

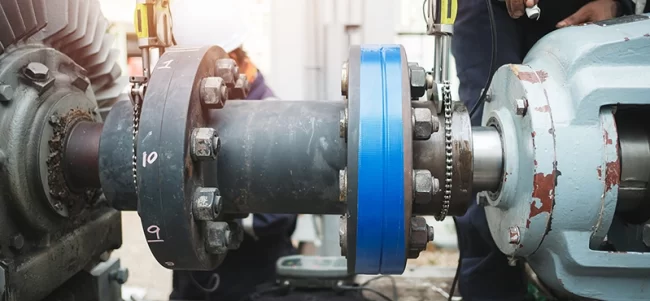

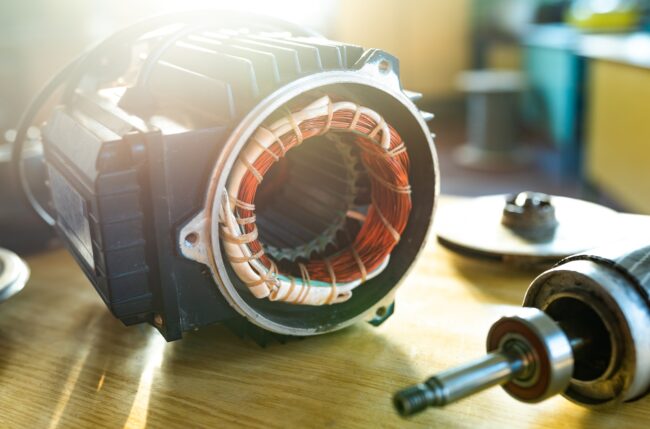

Electric Motor Maintenance Procedures

Those working with electric motors know that when it comes to maintaining the life of your equipment, electric motor maintenance best helps to reduce the chance of failure. Further, it improves the safety of your system. And, it helps to lower any downtime that you face because of any potential problems. We at Rocky Mount…