Why Should You Choose Motion Amplification for Electric Motors?

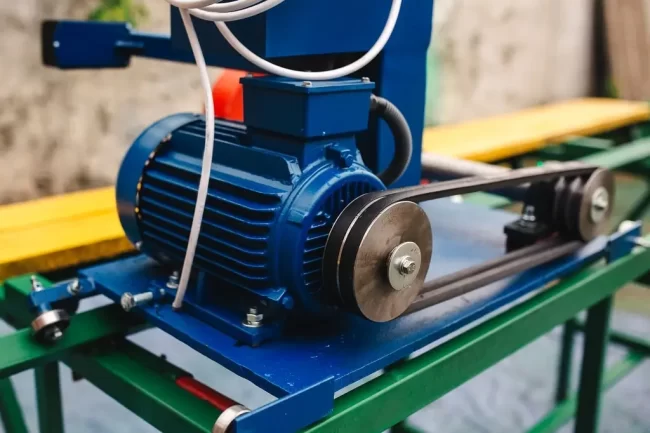

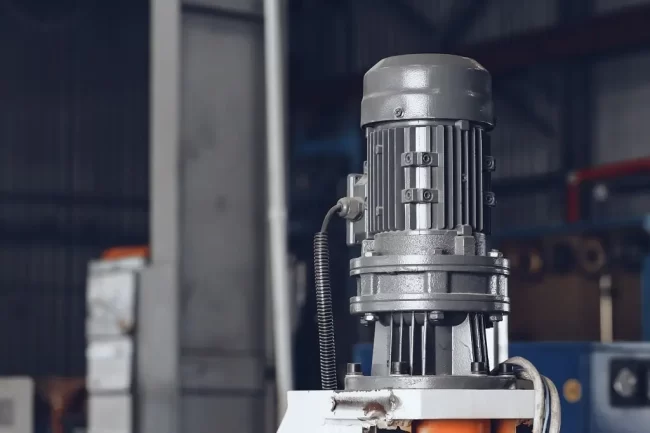

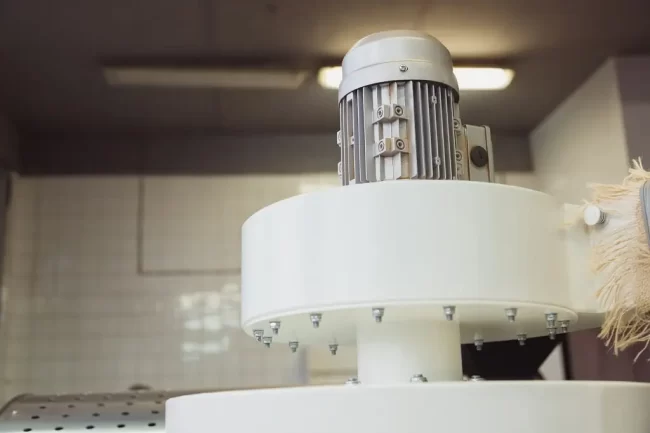

When assessing your industrial operation, motion amplification for electric motors helps assess and prevent future problems. Traditional diagnostic methods often require intrusive inspections or time-consuming manual measurements. This leaves room for errors or missed signs of wear and tear. However, advancements in technology have provided a powerful tool to address this challenge—motion amplification for electric…